Пыль -фильтр ткань

Отправить запрос

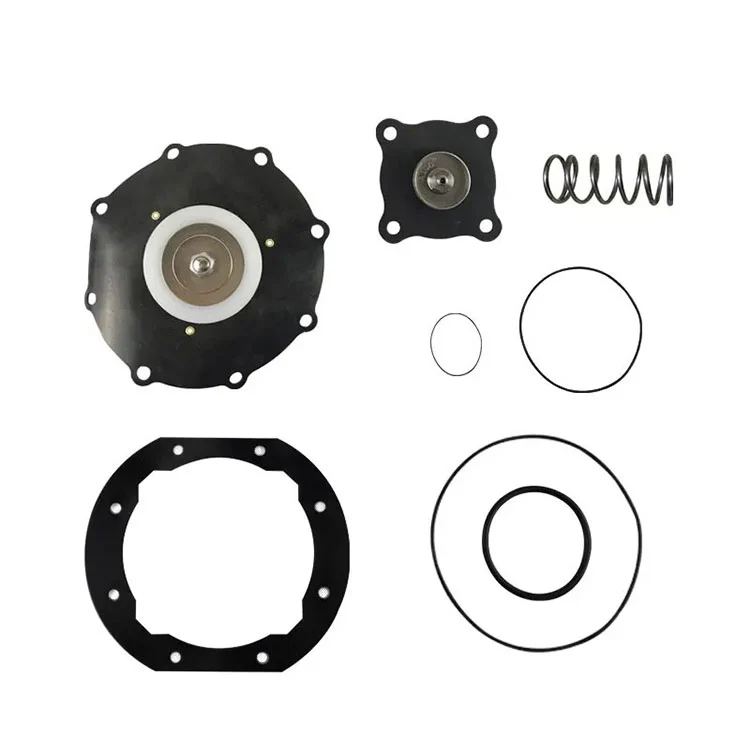

Product Description

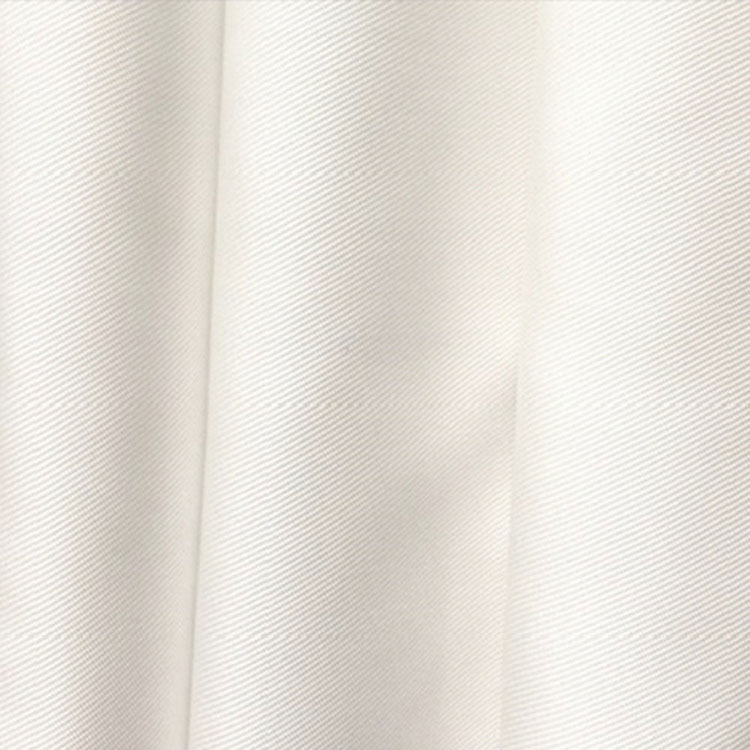

The Dust Filter Cloth specially designed to filter industrial dust and is an excellent filter material. The project uses high-quality synthetic fibres such as polypropylene (PP) and polyethylene (PE) through a unique method. The method is widely used in elimination devices in cement, metallurgy, energy, chemical engineering industry, waste burning and so on. The device can effectively capture micron-sized dust particles, ensure compliance with emission norms, and prolong the lifespan of filter bags. The substance is a basic filter for industrial environmental safeguarding.

Characteristics of the Dust Filter Cloth :

Adapt to various materials

The selection of substances such as PP, PE and PET depends on their operating environment to meet filtration needs at different temperatures (from -40°C to 130°C), acidic and alkaline conditions and dust properties.

Precise filtering framework

The design utilizes a gradient fiber layer. The outer layer is thick enough to trap fairly large particles, while the inner layer has gradient pores that effectively trap fine dust. filtration process efficiency can exceed 99.9%.

Superb longevity

Fiber weaving is known for its robustness and minimal elongation, excellent tensile and abrasion resistance. This product is high frequency pulse ash cleaning resistant, even if prolonged term usage will not deform or damage.

Cleaning surfaces is straightforward

You can choose film coating, sintering or other coating techniques to lessen surface stickiness, greatly improve ash cleaning and maintain consistency of filtration pressure difference.

Protecting the environment and ensuring security

It complies with RoHS regulations, does not emit toxic substances, can be recycled and regenerated, and aids businesses meet environmental production targets.

Advantages of Dust Filter Cloth:

Tailored assistance

Offers personalised capabilities such as graham (100-800g/m2), air permeability, thickness and width, and comes with different dust collectors, including pulse and reverse blow types.

Economy and excellence

It is designed with strong dust retention capacity, lessens dust cleaning regularity, prolonged replacement cycles, and reduced overall maintenance costs by over 30%.

Adapting to a tough work environments

Polypropylene filter fabric: alkali, suitable for use in coal-fired boiler and chemical dust.

PE filter cloth has its robust hydrolysis resistance in high humidity environment and is the first choice for waste incineration and biomass power.

Coated filter cloth: Effective instrument for capturing ultrafine dust particles (PM2.5)

Comprehensive life cycle assistance

Our range of technical advice extends from advising on selection, installation and commissioning to maintaining and optimizing systems to improve operational efficiency.

Areas of common application

Dust removal system for rotary kilns and coal mills in cement plants

Exhaust gases of boiler in thermal power station;

Purification of sintering machines and furnace gas in steelmaking equipment.

Filtering of filtering flue gas from coal-fired power plants

The chemical sector's focus focuses on powder recovery and volatile organic compounds (VOCs) treatment.